Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

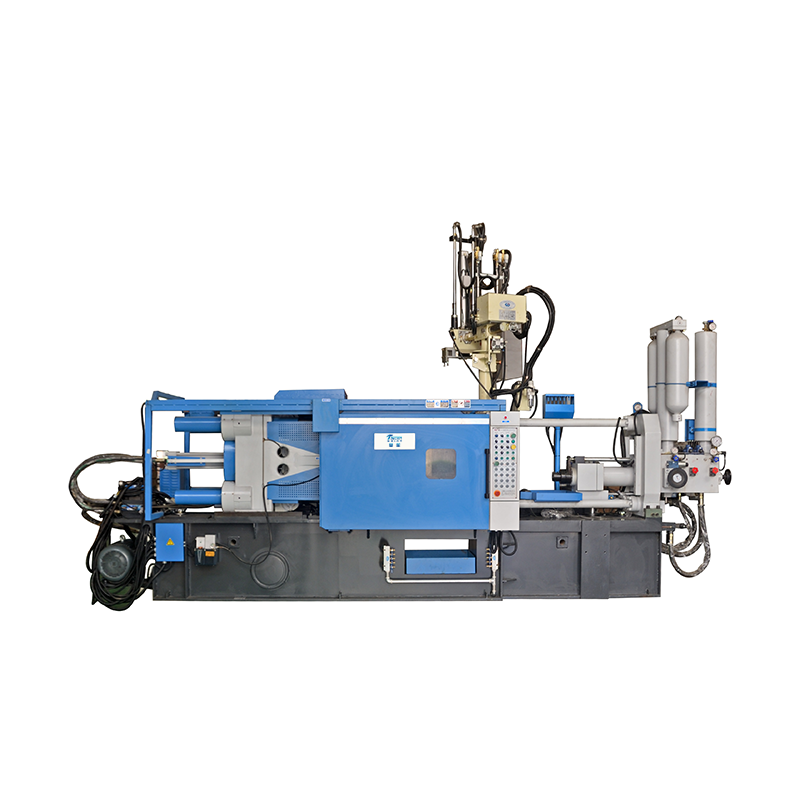

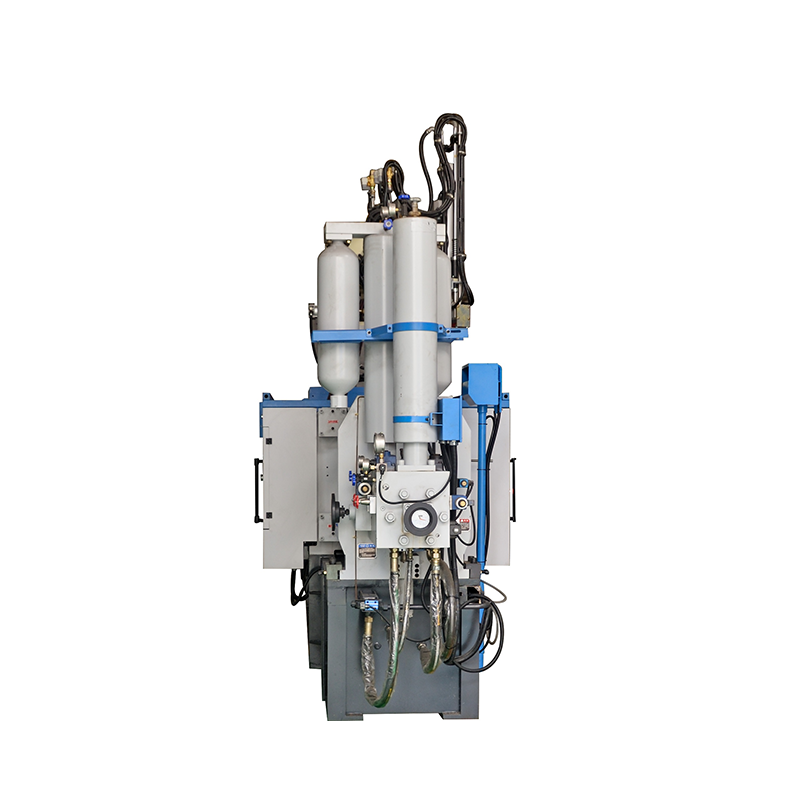

TSUENSAINT Cold Chamber Die Casting Machine Magnesium Alloy Products Clamping Force 1400kn-20800kn

The TSUENSAINT cold chamber die-casting machine, specifically crafted for magnesium alloy products. With a versatile clamping force spanning from 1400kN to 20800kN, this machine ensures precision and efficiency in the production of magnesium alloy components. Trust in a reliable solution designed to meet diverse manufacturing needs, delivering optimal performance across a broad clamping force range.

- Product Details

-

Download

Cold Chamber Die-Casting Machine

Product Description

The TSUENSAINT cold chamber die-casting machine is a specialized manufacturing equipment designed for the efficient production of high-quality metal components, particularly suited for alloys with high melting points such as aluminum, brass, and magnesium. This machine ensures precision by injecting molten metal into a cold chamber, allowing for intricate and complex part designs. With a robust and reliable construction, it caters to diverse industrial needs, offering a versatile solution for die-casting processes.

Product Features

- Versatile Clamping Force: Spanning from 1400kN to 20800kN, the machine accommodates diverse production needs for magnesium alloy products.

- Precision Die-Casting: Specifically designed for magnesium alloy, ensuring precise and intricate component production.

- Efficient Cooling System: Optimizes solidification for enhanced part quality in magnesium alloy die-casting.

- Advanced Control Technology: Ensures consistent and reliable production through precise control of injection and cooling processes.

Product Advantages

- Cost-Effective Production: The cold chamber die-casting machine stands out for its precision die-casting and efficient cooling, minimizing material waste and optimizing resource utilization. This feature ensures a cost-effective production process.

- Reduced Lead Times: With enhanced efficiency and precise control, the machine significantly reduces lead times in magnesium alloy product production. This is crucial for meeting tight production schedules and improving overall manufacturing timelines.

- Operator-Friendly Design: The cold chamber die-casting machine is thoughtfully designed for ease of operation. This user-friendly feature enables operators to efficiently manage the production process, minimizing errors and streamlining workflow for enhanced productivity.

- Compliance with Industry Standards: TSUENSAINT's cold chamber die-casting machine meets stringent industry standards. This ensures that manufacturers can confidently adhere to quality and safety regulations in the production of magnesium alloy products, aligning with industry best practices.

In search of a high-quality cold chamber die-casting machine? Look no further! We are dedicated to delivering superior quality and top-notch service to meet the needs of our customers.

Product Specification

| Specification | Tons | C/140D | C/200D | C/300D |

| Clamping force | KN | 1400 | 2000 | 3000 |

| Open Stroke | mm | 350 | 385 | 480 |

| Die-Thickness(Min-Max) | mm | 200-500 | 200-580 | 250-680 |

| Platen Size(H*V) | mm | 670x670 | 720x720 | 900x900 |

| Space Between Tie-bars | mm | 430x430 | 480x480 | 580x580 |

| Diameter of Tie-BarsΦ | mm | 80 | 85 | 110 |

| Injection Force | kN | 89-208 | 99-250 | 142-340 |

| Injection Stroke | mm | 335 | 370 | 440 |

| Injection Plunger Diameter | mm | 40,50 | 50,60 | 50,60,70 |

| Maxcasting volume(AL) | kg | 0.8,1.2 | 1.3,1.9 | 1.6,2.2,3.1 |

| Maxcasting volume(MG) | kg | 0.5,0.8 | 0.8,1.1 | 1,1.5,2 |

| Casting pressure | Mpa | 71-165.5 | 50.4-127.3 | 72.3-173 |

| (Min-Max) | 36.9-88.3 | |||

| Casting area | cm' | 83-305 | 141-700 | 162-759 |

| Injection Position | mm | 0,-100 | 0,-140 | 0,-160 |

| Plunger penetration | mm | 115 | 150 | 150 |

| Sleeve Flange DiameterΦ | mm | 110 | 110 | 110 |

| Sleeve Flange Protrusion | mm | 10 | 10 | 12 |

| Ejector force | kN | 109 | 109 | 180 |

| Ejector stroke | mm | 80 | 85 | 105 |

| Dry Cycle Time | s | 6 | 6 | 8 |

| System Working Pressure | Mpa | 16 | 16 | 16 |

| Motor Power | kW | 11 | 15 | 18.5 |

| Tank Capacity | L | 450 | 595 | 850 |

| Machine Weight | kg | 6000 | 7800 | 12500 |

| Overall Dimensions | mm | 5200x1265x2230 | 5510x1360x2530 | 6630x1640x2840 |

| of machine(L*W*H) |

| Specification | Tons | C/480D | C/500D | C/680D |

| Clamping force | KN | 4800 | 5800 | 6800 |

| Open Stroke | mm | 560 | 610 | 680 |

| Die-Thickness(Min-Max) | mm | 300-700 | 320-850 | 350-900 |

| Platen Size(H*V) | mm | 1010x1010 | 1150x1150 | 1290-1290 |

| Space Between Tie-bars | mm | 660x660 | 760x760 | 860x860 |

| Diameter of Tie-BarsΦ | mm | 130 | 140 | 160 |

| Injection Force | kN | 182-410 | 222-559 | 240-622 |

| Injection Stroke | mm | 550 | 580 | 640 |

| Injection Plunger Diameter | mm | 60,70,80 | 70,80,90 | 70,80,90 |

| Maxcasting volume(AL) | kg | 2.7,3.6,4.5 | 4.1,5.4,6.8 | 4.3,5.7,7.2 |

| Maxcasting volume(MG) | kg | 1.6,2.2,2.9 | 2.6,3.5,4.4 | 4.3,5.7,7.2 |

| Casting pressure | Mpa | 76-157 | 57.6-145 | 73.5-158.5 |

| (Min-Max) | 42.8-88.3 | 34.9-87.9 | 44.5-95.9 | |

| Casting area | cm' | 255-934 | 344-1433 | 397-1600 |

| Injection Position | mm | 0,-175 | 0,-230 | 0,-250 |

| Plunger penetration | mm | 200 | 230 | 280 |

| Sleeve Flange DiameterΦ | mm | 130 | 130 | 165 |

| Sleeve Flange Protrusion | mm | 15 | 15 | 15 |

| Ejector force | kN | 180 | 250 | 315 |

| Ejector stroke | mm | 125 | 150 | 150 |

| Dry Cycle Time | s | 8 | 10 | 12 |

| System Working Pressure | Mpa | 16 | 16 | 16 |

| Motor Power | kW | 22 | 30 | 37 |

| Tank Capacity | L | 900 | 1000 | 1000 |

| Machine Weight | kg | 16500 | 24000 | 31000 |

| Overall Dimensions | mm | 7200x1700x2950 | 8010x1985x2940 | 8400x2100x3000 |

| of machine(L*W*H) |

| Specification | Tons | C/880D | C/1080D | C/1380D | |

| Clamping force | KN | 8800 | 10800 | 13800 | |

| Open Stroke | mm | 760 | 880 | 1000 | |

| Die-Thickness(Min-Max) | mm | 400-950 | 450-1150 | 450-1200 | |

| Platen Size(H*V) | mm | 1400x1400 | 1620x1660 | 1800x1800 | |

| Space Between Tie-bars | mm | 910x910 | 1030x1030 | 1100x1100 | |

| Diameter of Tie-BarsΦ | mm | 180 | 200 | 230 | |

| Injection Force | kN | 253-680 | 865 | 440-1100 | |

| Injection Stroke | mm | 760 | 800 | 945 | |

| Injection Plunger Diameter | mm | 80,90,100 | 90-120 | 100-140 | |

| Maxcasting volume(AL) | kg | 6.7,8.4,10.4 | 9.9,12,14.8,17.5 | 13-25 | |

| Maxcasting volume(MG) | kg | 4.3,5.4,6.7 | 7.9-12.9 | 89-174 | |

| Casting pressure | Mpa | 50.3-123.7 | 76-136 | 71.4-140 | |

| (Min-Max) | 32.2-79 | ||||

| Casting area | cm' | 646-2484 | 735-2500 | 893-4371 | |

| Injection Position | mm | -140,-280 | -150,-300 | -160,-320 | |

| Plunger penetration | mm | 290 | 300 | 350 | |

| Sleeve Flange DiameterΦ | mm | 180 | 240 | 240 | |

| Sleeve Flange Protrusion | mm | 20 | 20 | 25 | |

| Ejector force | kN | 320 | 500 | 580 | |

| Ejector stroke | mm | 180 | 200 | 205 | |

| Dry Cycle Time | s | 12 | 15 | 16 | |

| System Working Pressure | Mpa | 16 | 16 | 16 | |

| Motor Power | kW | 37 | 45 | 2x37 | |

| Tank Capacity | L | 1100 | 1900 | 2500 | |

| Machine Weight | kg | 39000 | 70000 | 98000 | |

| verall Dimensions | mm | 9960x2450x3330 | 10600x3500x3800 | 12000x3400x4000 | |

| of machine(L*W*H) | |||||

| Specification | Tons | C/1680D | C/2080D | ||

| Clamping force | KN | 16800 | 20800 | ||

| Open Stroke | mm | 1200 | 1400 | ||

| Die-Thickness(Min-Max) | mm | 500-1400 | 650-1600 | ||

| Platen Size(H*V) | mm | 2020x2020 | 2150x2150 | ||

| Space Between Tie-bars | mm | 1190x1190 | 1350x1350 | ||

| Diameter of Tie-BarsΦ | mm | 250 | 280 | ||

| Injection Force | kN | 1290 | 1500 | ||

| Injection Stroke | mm | 980 | 960 | ||

| Injection Plunger Diameter | mm | 110-150 | 130-170 | ||

| Maxcasting volume(AL) | kg | 17-32 | 25-42 | ||

| Maxcasting volume(MG) | kg | 12.2-23 | 15.8-28 | ||

| Casting pressure | Mpa | 73-135.7 | 66-113 | ||

| (Min-Max) | |||||

| Casting area | cm' | 1223-5866 | 1770-6000 | ||

| Injection Position | mm | -175,-350 | -175,-350 | ||

| Plunger penetration | mm | 400 | 400 | ||

| Sleeve Flange DiameterΦ | mm | 260 | 260 | ||

| Sleeve Flange Protrusion | mm | 25 | 30 | ||

| Ejector force | kN | 620 | 650 | ||

| Ejector stroke | mm | 250 | 300 | ||

| Dry Cycle Time | s | 20 | 22 | ||

| System Working Pressure | Mpa | 16 | 16 | ||

| Motor Power | kW | 2x45 | 2x55 | ||

| Tank Capacity | L | 2600 | 3500 | ||

| Machine Weight | kg | 108000 | 135000 | ||

| verall Dimensions | mm | 12200x3000x4200 | 13700x4700x4900 | ||

| of machine(L*W*H) | |||||

Download

-

COLD CHAMBER.pdf

Download COLD CHAMBER.pdf