Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

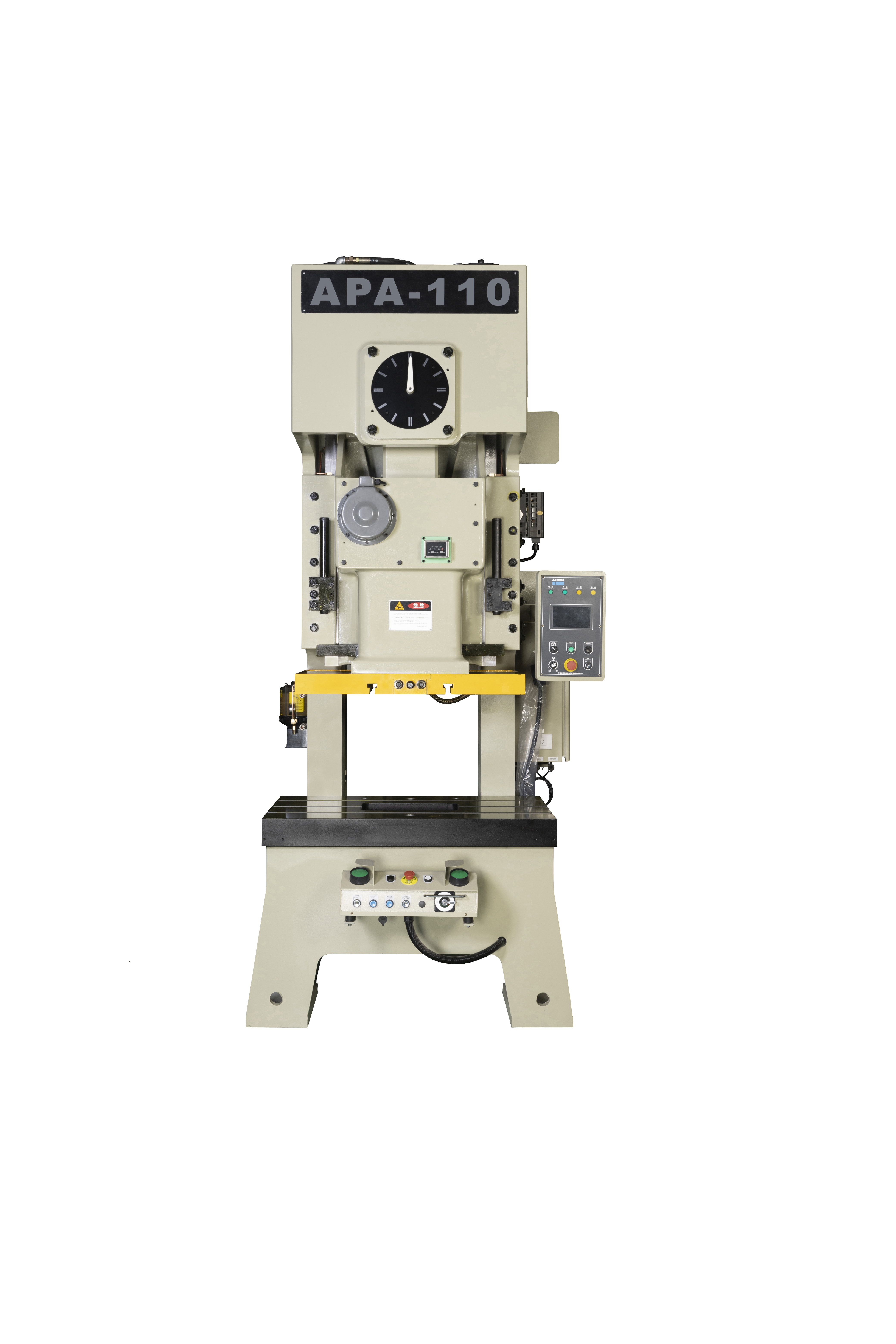

TSUENSAINT APA Series High Precision Punching Machine APA15-400T

Discover the TSUENSAINT APA series high precision punching machine (APA15-400T). Engineered for precision, the machine body is expertly welded using premium quality steel sheet and undergoes meticulous tension elimination treatment. This not only enhances stability but also ensures the utmost reliability in precision operations. Elevate your manufacturing processes with the APA Series, a testament to cutting-edge technology and unwavering dependability.

- Product Details

-

Download

High Precision Punching Machine

Product Description

Explore the TSUENSAINT APA series high precision punching machine (APA15-400T), a pinnacle of cutting-edge engineering. The machine boasts a robust body crafted from premium steel sheet, treated for tension elimination, ensuring heightened stability and reliability in precision operations. With unwavering commitment to top-notch manufacturing, the APA Series stands as the ideal choice for industries requiring precision excellence in their punching processes. Elevate your production capabilities with this technologically advanced and reliable punching machine.

Product Features

- Premium Construction: Crafted from high-quality steel sheet for durable and stable precision punching.

- Tension Elimination Treatment: Meticulous treatment ensures reliable, consistent, and precise machine performance.

- Cutting-Edge Engineering: Incorporates advanced technology for superior precision and operational efficiency.

- Unparalleled Performance: A top-notch choice for reliable precision excellence in various industries.

Product Advantages

- Minimized Vibrations: The high precision punching machine employs a robust construction that effectively minimizes vibrations. The reduction in vibrations enhances the overall operational experience by ensuring accuracy and consistency in each punch.

- Top-Notch Manufacturing: The high precision punching machine, part of the punching machine, distinguishes itself with a commitment to top-notch manufacturing. The machine is meticulously crafted to deliver reliable and consistent results, making it a trusted choice for precision applications.

- Adaptable Technology: The high precision punching machine incorporates adaptable and advanced technology, positioning it at the forefront of the industry. This adaptability ensures that the machine remains versatile and capable of meeting evolving manufacturing needs.

- Environmental Impact: Beyond its operational prowess, the machine is designed with environmental sustainability in mind. By aligning with sustainable manufacturing practices, the high precision punching machine exemplifies a responsible approach to industrial production, minimizing its ecological footprint.

Whether you seek top-quality high precision punching machines or cost-effective options, we provide tailored solutions to meet your specific needs! Explore our comprehensive selection to find the perfect machine that aligns with your needs, ensuring optimal performance and efficiency in your punching operations.

Product Specification

| Specification | APA-15 | APA-25 | |||||||

| Model | V | V | H | S | |||||

| Capacity | Ton | 15 | 25 | ||||||

| Rated tonnage point | mm | 3.2 | 1.6 | 3.2 | |||||

| Speed changing | s.p.m | 120-180 | 60-140 | 130-200 | 60-120 | ||||

| Stroke | mm | 60 | 70 | 30 | 80 | ||||

| Die height | mm | 200 | 195 | 215 | 195 | ||||

| Slide adjustment | mm | 50 | 50 | ||||||

| Slide area | mm | 300×230×50 | 300×230×50 | ||||||

| Bolster area | mm | 680×300×70 | 680×300×70 | 680×300×65 | |||||

| Shank hole | mm | Φ38.1 | Φ38.1 | ||||||

| Main motor | kw.p | 2.2×6 | 3.7×4 | ||||||

| Slide adjust device | HP | manual operation | |||||||

| Air pressure | kg/cm | 6 | 6 | ||||||

| Presses precision | GB/JIS 1class | ||||||||

| Presses dimension | mm | 1360×930×2100 | 1450×985×2300 | ||||||

| Specification | APA-35 | APA-45 | APA-60 | ||||||||||

| Model | V | H | V | H | V | H | |||||||

| Capacity | Ton | 35 | 45 | 60 | |||||||||

| Rated tonnage point | mm | 3.2 | 1.6 | 3.2 | 1.6 | 4 | 2 | ||||||

| Speed changing | s.p.m | 40-120 | 110-180 | 40-100 | 110-150 | 35~90 | 80-120 | ||||||

| Stroke | mm | 70 | 40 | 80 | 50 | 120 | 60 | ||||||

| Die height | mm | 220 | 235 | 250 | 265 | 310 | 340 | ||||||

| Slide adjustment | mm | 55 | 60 | 75 | |||||||||

| Slide area | mm | 360×250×50 | 400×300×60 | 500×360×70 | |||||||||

| Bolster area | mm | 800×400×70 | 850×440×80 | 900×500×80 | |||||||||

| Shank hole | mm | Φ38.1 | Φ38.1 | Φ50 | |||||||||

| Main motor | kw.p | 3.7×4 | 5.5×4 | 5.5×4 | |||||||||

| Slide adjust device | HP | manual operation | |||||||||||

| Air pressure | kg/cm | 6 | 6 | 6 | |||||||||

| Presses precision | GB/JIS 1class | ||||||||||||

| Presses dimension | mm | 1480×1055×2450 | 1680×1105×2600 | 1700×1155×2900 | |||||||||

| Specification | APA-80 | APA-110 | APA-125 | ||||||||||

| Model | V | H | V | H | V | H | |||||||

| Capacity | Ton | 80 | 110 | 125 | |||||||||

| Rated tonnage point | mm | 4 | 2 | 6 | 3 | 5 | 3 | ||||||

| Speed changing | s.p.m | 35-80 | 80-120 | 30-60 | 60-9C | 35-65 | 45-8C | ||||||

| Stroke | mm | 150 | 70 | 180 | 80 | 160 | 100 | ||||||

| Die height | mm | 340 | 380 | 360 | 410 | 370 | 400 | ||||||

| Slide adjustment | mm | 80 | 80 | 90 | |||||||||

| Slide area | mm | 560×420×70 | 650×470×80 | 620×520×80 | |||||||||

| Bolster area | mm | 1000×550×90 | 1150×600×110 | 1120×720×120 | |||||||||

| Shank hole | mm | Φ50 | Φ50 | Φ70 | |||||||||

| Main motor | kw.p | 7.5×4 | 11×4 | 11×4 | |||||||||

| Slide adjust device | HP | clectrial driving | |||||||||||

| Air pressure | kg/cm | 6 | 6 | 6 | |||||||||

| Presses precision | GB/JIS 1class | ||||||||||||

| Presses dimension | mm | 1875×1330×3100 | 2000×1460×3350 | 2070×1530×3250 | |||||||||

| Die cushion capacity | Ton | 3.6 | 6 | 3.6 | |||||||||

| Stroke | mm | 70 | 85 | 70 | |||||||||

| Die cushion effective area | mm² | 440×300 | 490×350 | 440×300 | |||||||||

| Specification | APA-160 | APA-200 | APA-260 | ||||||||||

| Model | V | H | V | H | V | H | |||||||

| Capacity | Ton | 160 | 200 | 250 | |||||||||

| Rated tonnage point | mm | 6 | 3 | 6 | 3 | 7 | 3.5 | ||||||

| Speed changing | s.p.m | 30-55 | 35-70 | 25-50 | 30-60 | 25-45 | 30-50 | ||||||

| Stroke | mm | 180 | 110 | 200 | 130 | 220 | 150 | ||||||

| Die height | mm | 400 | 435 | 450 | 485 | 500 | 535 | ||||||

| Slide adjustment | mm | 11 | 110 | 110 | |||||||||

| Slide area | mm | 700×580×100 | 850×650×100 | 880×700×100 | |||||||||

| Bolster area | mm | 1260×760×140 | 1400×820×160 | 1500×840×180 | |||||||||

| Shank hole | mm | Φ70 | Φ70 | Φ70 | |||||||||

| Main motor | kw.p | 15×4 | 18.5×4 | 22×4 | |||||||||

| Slide adjust device | HP | clectrial driving | |||||||||||

| Air pressure | kg/cm | 6 | 6 | 6 | |||||||||

| Presses precision | GB/JIS 1class | ||||||||||||

| Presses dimension | mm | 2260×1690×3600 | 2468×1890×3910 | 2730×1982×4050 | |||||||||

| Die cushion capacity | Ton | 8 | 10 | 14 | |||||||||

| Stroke | mm | 85 | 80 | 100 | |||||||||

| Die cushion effective area | mm² | 490×350 | 640×420 | 710×480 | |||||||||

| Specification | APA-315 | APA-400 | |||||||

| Model | V | H | V | H | |||||

| Capacity | Ton | 315 | 400 | ||||||

| Rated tonnage point | mm | 8 | 4 | 8 | 4 | ||||

| Speed changing | s.p.m | 25-40 | 25-50 | 25-35 | 25-30 | ||||

| Stroke | mm | 250 | 180 | 250 | 180 | ||||

| Die height | mm | 500 | 585 | 550 | 585 | ||||

| Slide adjustment | mm | 120 | 120 | ||||||

| Slide area | mm | 950×700×110 | 950×700×110 | ||||||

| Bolster area | mm | 1650×840×180 | 1800×840×190 | ||||||

| Shank hole | mm | ||||||||

| Main motor | kw.p | 30×4 | 37×4 | ||||||

| Slide adjust device | HP | clectrial driving | |||||||

| Air pressure | kg/cm | 6 | 6 | ||||||

| Presses precision | GB/JIS 1class | ||||||||

| Presses dimension | mm | 2900×2060×4530 | 3020×22604600 | ||||||

| Die cushion capacity | Ton | 14 | 14 | ||||||

| Stroke | mm | 100 | 100 | ||||||

| Die cushion effective area | mm² | 810×480 | 810×480 | ||||||

Download

-

APA.pdf

Download APA.pdf