Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

Periphreal Machine

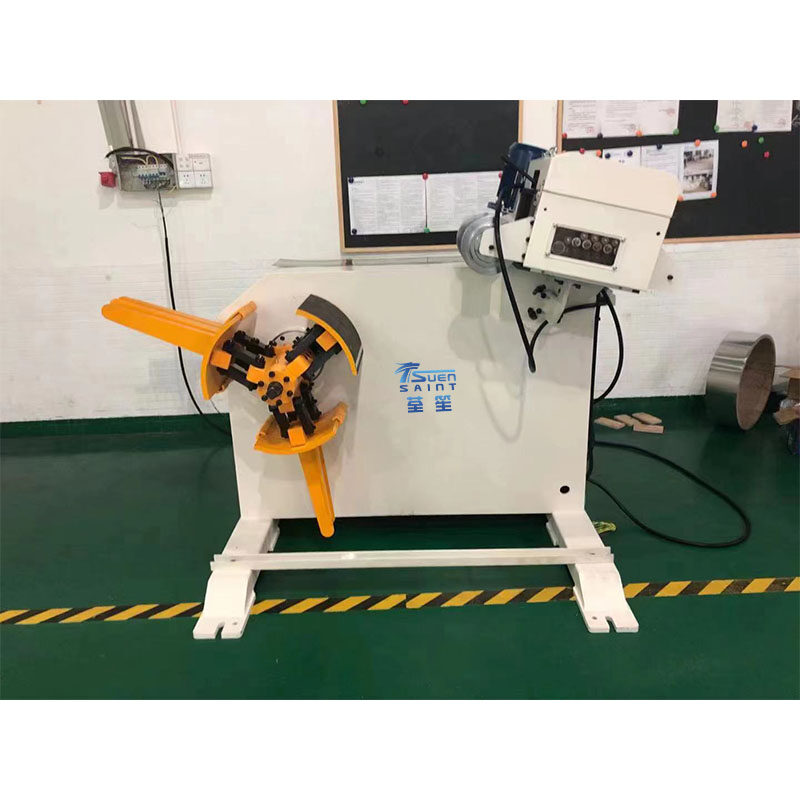

(14)Uncoiler Straightener Feeder For Punching Machine

The uncoiler straightener feeder for punching machines stands as a pinnacle of engineering excellence, seamlessly marrying precision and efficiency in material feeding for metalworking. Meticulously designed, this integrated system transforms the mundane into an art, synchronizing uncoiling, straightening, and feeding processes. Its fluid operation ensures a continuous and uninterrupted workflow, this not only optimizes productivity but redefines the very essence of efficiency in the intricate realm of metal punching operations.

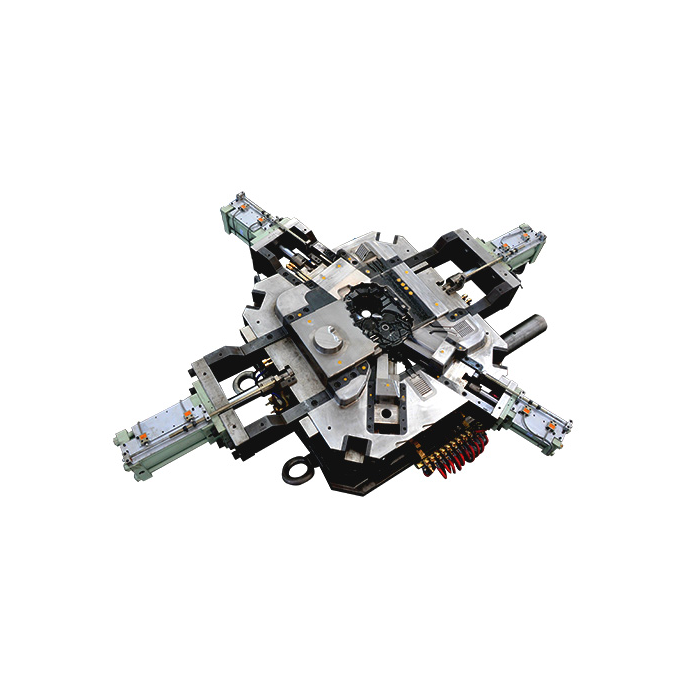

Quick Die Change System For Punching Machine

The quick die change system for punching machines is a groundbreaking solution specifically designed to streamline and expedite the die changeover process, thereby significantly enhancing operational efficiency in industrial settings. This innovative system represents a game-changing approach to the setup process for punching machines, with a primary focus on minimizing downtime and maximizing overall productivity.

Metal Sheet Stainless Steel Straightener Leveler And Flatten Machine Coil Uncoiler And Straightener

The metal sheet stainless steel straightener, a state-of-the-art machine seamlessly integrating leveling and flattening capabilities. Teamed with a coil uncoiler, this comprehensive solution is meticulously crafted to optimize the metal sheet processing workflow. Experience a revolution in your metalworking operations, where precision and efficiency converge to elevate the standards of your manufacturing processes.

Crucible Melting Furnace For Aluminum Alloy Die Casting Machine

The crucible melting furnace, a pivotal component designed exclusively for aluminum alloy die casting machines. Positioned at the forefront of innovation, this furnace plays a pivotal role in redefining the crucial melting phase within die-casting processes. Let's delve into the intricate details of this advanced melting solution, meticulously crafted for precision, efficiency, and an elevation in die-casting capabilities.

Mold service

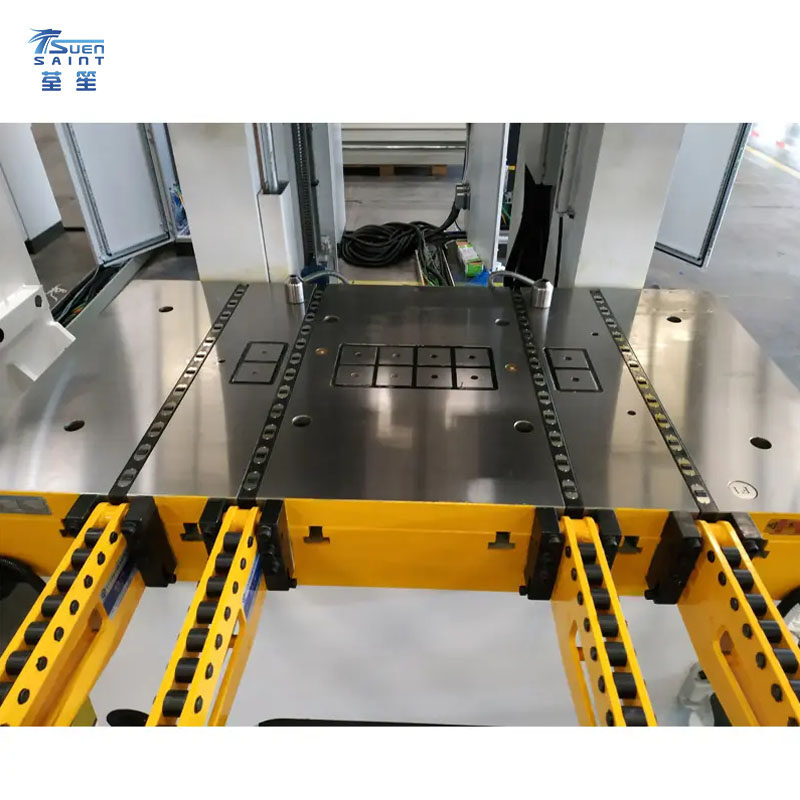

(4)Die Splitter Separador de Molds

The die splitter separador de molds is an essential tool in the manufacturing industry, specifically designed to efficiently and safely split molds and dies for maintenance, repair, or replacement purposes. With its robust construction and versatile features, it streamlines the process of separating molds, ensuring minimal downtime and maximum productivity in industrial settings.

High Precision Standard Punch Press mold

Crafted with meticulous precision, our high precision standard punch press mold stands as a pinnacle of quality in the manufacturing industry. Engineered to deliver consistent and accurate results, it is designed to meet the rigorous demands of modern production environments. With its durable construction and precise machining, this mold ensures reliable performance and high-quality output for various punching applications.

High precision zinc alloy aluminum die casting mold

Crafted with meticulous engineering and craftsmanship, our high precision zinc alloy aluminum die casting mold is tailored to meet the rigorous demands of the die casting industry. It guarantees precise and efficient production of zinc alloy and aluminum components, ensuring dimensional accuracy and surface finish. This mold is a reliable solution for achieving high-quality results in die casting operations.

Plastic injection mold PVC pipe fitting mold Bottle preform mold Plastic product mold

Plastic injection molds for PVC pipe fitting molds are specialized tools designed to produce precise and high-quality PVC pipe fittings. These molds are crafted with precision engineering to ensure accurate and consistent molding of PVC materials. They play a crucial role in the manufacturing process, allowing for efficient and reliable production of PVC pipe fittings with various shapes and sizes.

Machining Centre & Parts

(11)TSUENSAINT LS Series Liner Motor High speed Machine Center

Engineered with state-of-the-art linear motor technology, the TSUENSAINT LS series liner motor high speed machine center delivers exceptional performance and precision. Its high-speed capabilities enable rapid machining of complex parts with unmatched accuracy and surface finish. With a robust and ergonomic design, this machine center ensures smooth operation and ease of use in demanding manufacturing environments.

TSUENSAINT YMC Series CNC Engraving and Milling Machine

The TSUENSAINT YMC series CNC engraving and milling machine is engineered for precision machining, featuring advanced capabilities and sturdy construction. It excels in a variety of engraving and milling tasks, ensuring superior performance and reliability. From intricate designs to complex projects, this machine offers versatility and accuracy, making it an ideal choice for various industrial applications.

TSUENSAINT YMC Series Vertical Machining Center

The TSUENSAINT YMC series vertical machining center features a vertical spindle orientation, ideal for vertical milling, drilling, and tapping operations. Its compact design optimizes space utilization, while its versatile capabilities accommodate diverse machining needs, ranging from prototype development to large-scale production. With precision engineering and advanced technology, it delivers efficient and reliable performance in industrial machining applications.

TSUENSAINT GT Series CNC High Speed Double Column Machine Center

The TSUENSAINT GT series CNC high-speed double column machine center is an innovative solution for precision machining tasks. With its advanced technology and robust construction, it delivers superior performance and versatility to meet diverse industrial needs. From high-speed cutting to intricate detailing, this machine center offers efficiency and reliability for a wide range of machining applications.