Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

Two Color Injection Molding Machine Exporter: The Key to Advanced Manufacturing Solutions

In the ever-evolving world of manufacturing, businesses are continuously seeking innovative technologies that can boost production efficiency, improve product quality, and reduce costs. One such technology that has gained significant traction is two color injection molding machines. These machines are essential for industries that require intricate designs, multi-material applications, and high-quality finishes. As a two color injection molding machine exporter, your role in delivering these advanced solutions to global manufacturers is more important than ever. In this blog, we will explore why these machines are in demand, the advantages they offer, and how partnering with the right exporter can enhance your production processes.

Understanding Two Color Injection Molding Machines

Before diving into the specifics of being a two color injection molding machine exporter, it’s crucial to understand how these machines work and their significance in the manufacturing industry.

What is a Two Color Injection Molding Machine?

A two color injection molding machine is designed to inject two different materials or colors into a single mold. This allows manufacturers to create multi-colored or multi-material products in one production cycle. The process ensures precise layering or blending of materials, creating a product that is both functional and aesthetically appealing.

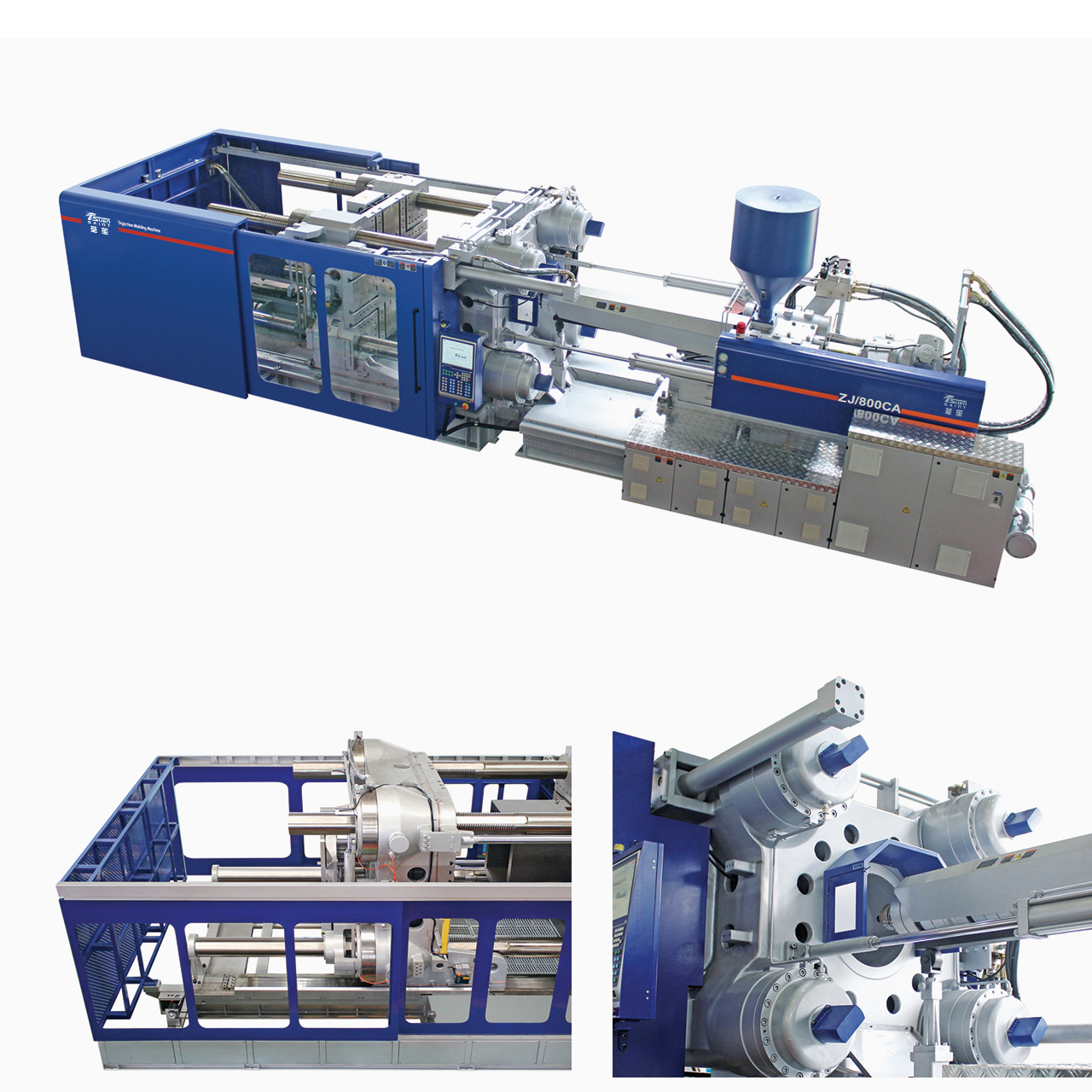

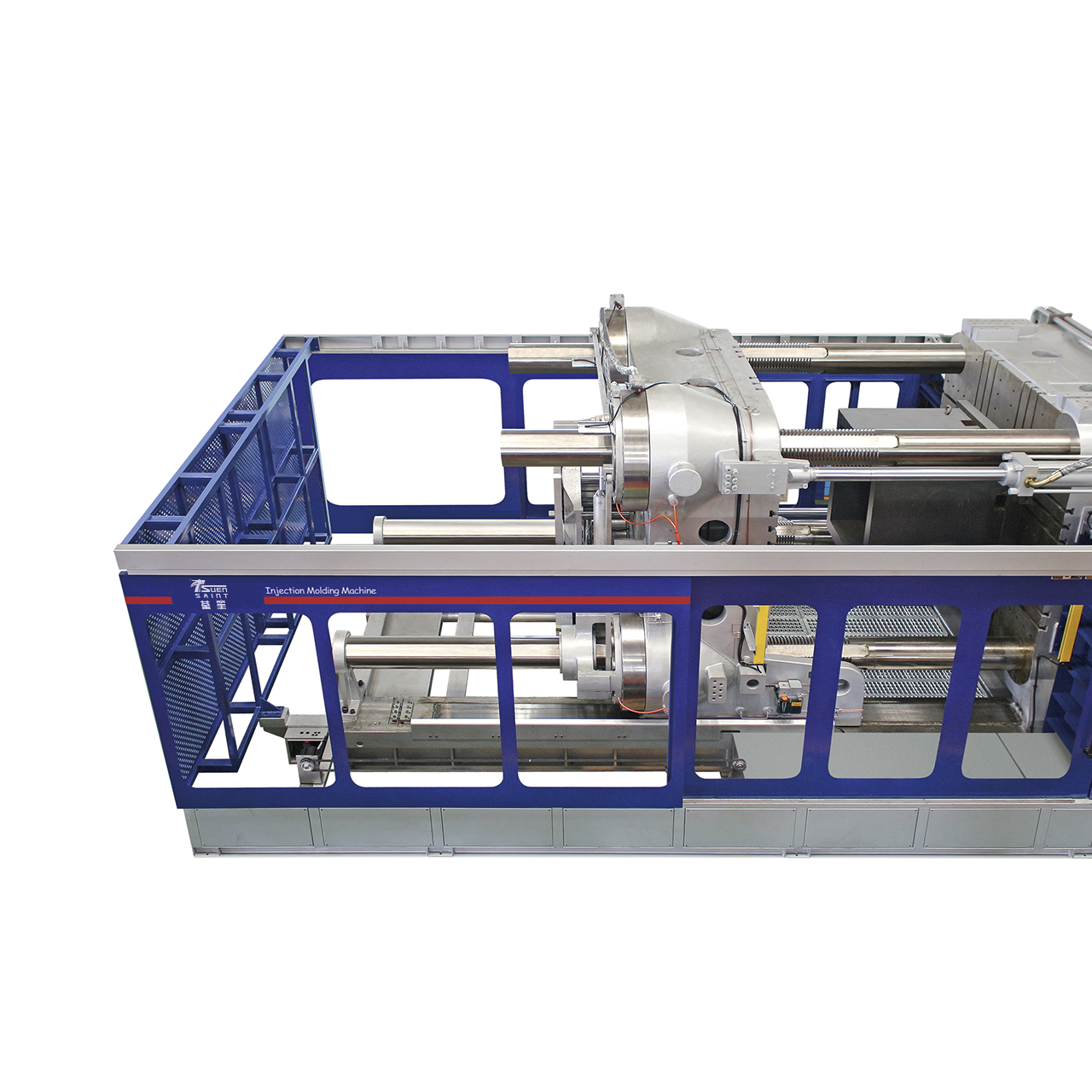

Key Components of Two Color Injection Molding Machines

Two Injection Units: The primary feature of this machine is its two injection units, which allow for the simultaneous injection of two different materials or colors.

Rotating Platen: The rotating platen shifts the mold after the first injection to allow for the second material to be injected in the correct area.

Mold Design: These machines use specialized molds designed to handle the two-color or two-material process without compromising product integrity.

Applications of Two Color Injection Molding

Two color injection molding machines are widely used across various industries, including automotive, consumer electronics, medical devices, and household goods. These machines are particularly beneficial for products that require enhanced aesthetic appeal or complex material properties.

For instance, in the automotive industry, two-color injection molding machines are used to create dashboards, handles, and control buttons with multi-material surfaces for both functional and design purposes. In the consumer electronics sector, these machines help create sleek, multi-colored phone cases and electronic device components.

Why Manufacturers Prefer Two Color Injection Molding Machines

1. Improved Product Aesthetics

One of the main reasons manufacturers choose two color injection molding machines is the ability to create visually appealing products. With two colors or materials, manufacturers can design products that stand out from the competition, offering enhanced customization options for their clients.

2. Enhanced Durability and Functionality

Combining two different materials in one product can improve its functionality. For example, a product may require both rigid and flexible materials to enhance its performance. By using a two-color injection molding machine, manufacturers can combine these materials in one seamless production process.

3. Cost-Effective Production

Although two color injection molding machines represent a significant investment, they offer long-term cost savings by reducing the need for multiple production cycles. With these machines, manufacturers can complete the production of complex parts in one go, significantly reducing labor and material costs.

4. Increased Production Efficiency

The two-color molding process eliminates the need for secondary processing, such as painting or assembling parts with different materials. This increases overall production efficiency, enabling manufacturers to meet tight deadlines and produce large quantities without compromising on quality.

The Role of a Two Color Injection Molding Machine Exporter

1. Providing High-Quality Machines

As a two color injection molding machine exporter, your primary role is to supply high-quality machines to manufacturers worldwide. These machines must meet international standards and offer advanced features that improve production capabilities. Your expertise in selecting and exporting the right machines can make or break a manufacturer’s ability to compete in their respective markets.

2. Customizing Solutions for Specific Industries

Manufacturers across various industries have unique needs, and your ability to provide tailored solutions is crucial. Whether your clients need machines with high precision for medical device manufacturing or large-scale production capabilities for the automotive sector, offering customizable machines is key to satisfying diverse market demands.

For example, offering ODM (Original Design Manufacturer) services, such as an odm servotype injection molding machine, can help you cater to specific client needs. By collaborating closely with manufacturers, you can deliver specialized machines that enhance their production efficiency and product quality.

3. Offering Comprehensive Support and Maintenance

Exporting two color injection molding machines is just the beginning. Providing ongoing support, maintenance, and training is essential to building long-term relationships with your clients. Manufacturers rely on exporters who not only deliver high-quality machines but also offer the expertise and guidance needed to keep those machines running at peak performance.

How to Choose the Right Two Color Injection Molding Machine Exporter

With the growing demand for two color injection molding machines, it’s important for manufacturers to partner with the right exporter. Here are some key factors to consider when choosing an exporter:

1. Experience and Expertise

An experienced two color injection molding machine exporter will have a deep understanding of the technology and its applications across various industries. Look for exporters with a proven track record of delivering high-quality machines that meet your specific production needs.

2. Customizable Solutions

Every manufacturing process is different, so you need an exporter who can offer customizable solutions. Whether it’s machine size, capacity, or specific features, the right exporter will work closely with you to provide the perfect machine for your requirements.

3. Global Reach and Logistics Expertise

Exporting large, complex machinery requires extensive knowledge of international logistics, customs regulations, and shipping procedures. Choose an exporter who has the infrastructure and expertise to ensure smooth and timely delivery of your machines, no matter where you are in the world.

4. After-Sales Support

The relationship with your exporter shouldn’t end once the machine is delivered. Choose an exporter who offers comprehensive after-sales support, including maintenance, spare parts, and technical training. This will ensure that your two color injection molding machine operates efficiently for years to come.

Future Trends in Two Color Injection Molding Machines

The demand for two color injection molding machines is expected to grow as manufacturers continue to push for more complex, high-quality products. Several trends are shaping the future of this technology:

1. Integration with Industry 4.0

As smart manufacturing becomes more prevalent, two color injection molding machines will increasingly integrate with Industry 4.0 technologies. This will include features like real-time monitoring, predictive maintenance, and automated quality control, all aimed at improving efficiency and reducing downtime.

2. Sustainable Manufacturing

Sustainability is a major focus for manufacturers, and two color injection molding machines are evolving to meet these demands. Manufacturers are seeking machines that use less energy, reduce waste, and support the use of recycled materials. Exporters who offer eco-friendly machines will be well-positioned to meet this growing demand.

3. Advancements in Materials

As material science advances, two color injection molding machines will continue to play a critical role in creating innovative products. New materials with enhanced properties, such as lightweight composites and bio-based plastics, will expand the applications of these machines across various industries.

Conclusion: Unlocking New Possibilities with Two Color Injection Molding Machines

In today’s competitive manufacturing landscape, having access to advanced technologies like two color injection molding machines is essential for staying ahead. As a two color injection molding machine exporter, you have the opportunity to provide manufacturers with the tools they need to produce high-quality, innovative products efficiently and cost-effectively.

By understanding the unique needs of your clients, offering customizable solutions, and providing ongoing support, you can become a valuable partner in their success. As demand for multi-material products grows, so too will the importance of these machines in driving the future of manufacturing.

Make the right choice by partnering with a trusted two color injection molding machine exporter, and watch your manufacturing capabilities soar to new heights.