Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

Periphreal Machine

Periphreal Machine

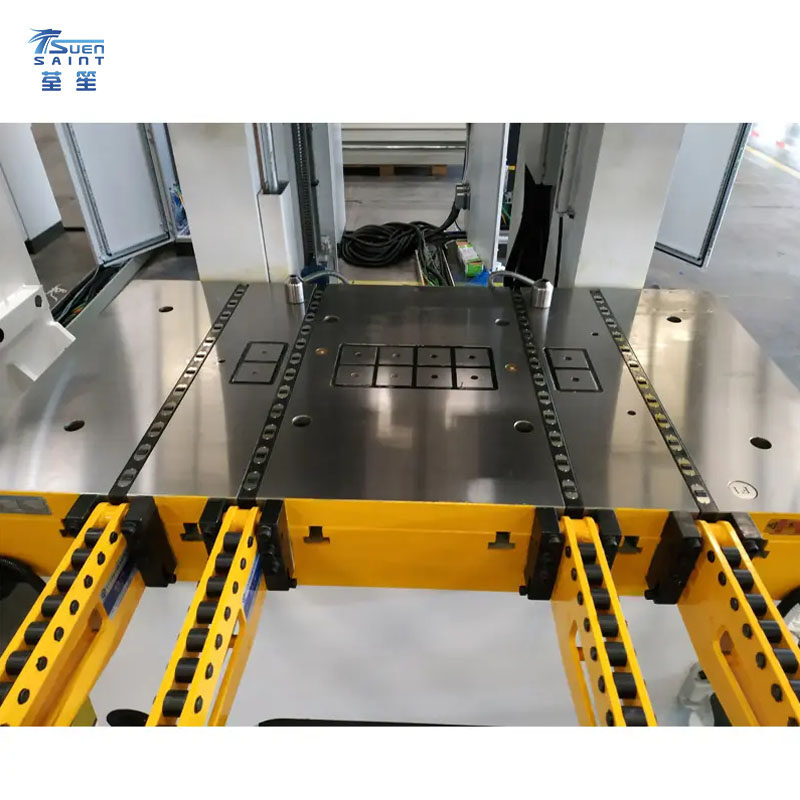

(14)Quick Die Change System For Punching Machine

The quick die change system for punching machines is a groundbreaking solution specifically designed to streamline and expedite the die changeover process, thereby significantly enhancing operational efficiency in industrial settings. This innovative system represents a game-changing approach to the setup process for punching machines, with a primary focus on minimizing downtime and maximizing overall productivity.

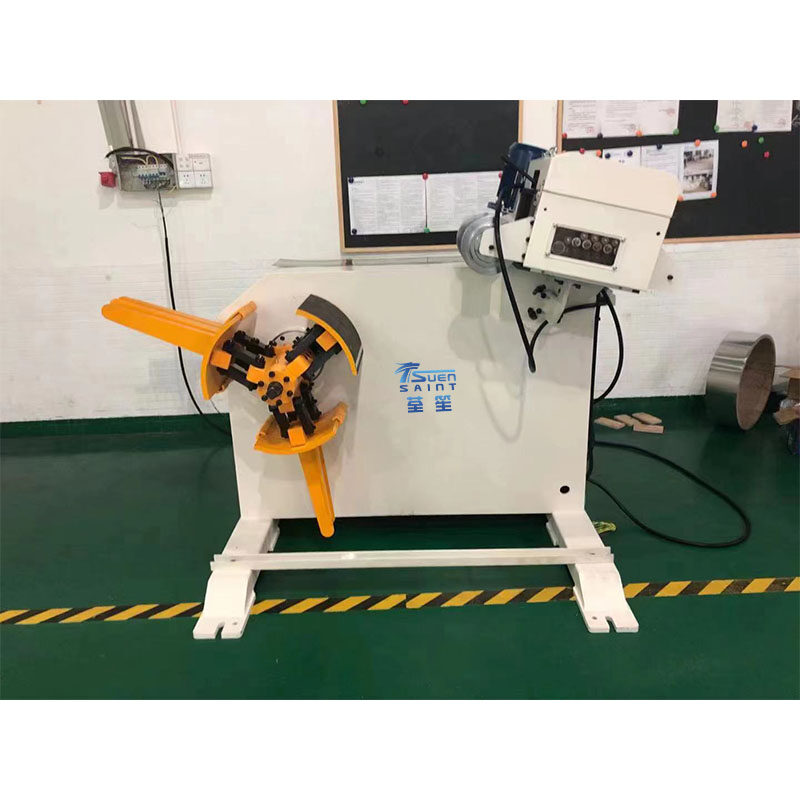

Metal Sheet Stainless Steel Straightener Leveler And Flatten Machine Coil Uncoiler And Straightener

The metal sheet stainless steel straightener, a state-of-the-art machine seamlessly integrating leveling and flattening capabilities. Teamed with a coil uncoiler, this comprehensive solution is meticulously crafted to optimize the metal sheet processing workflow. Experience a revolution in your metalworking operations, where precision and efficiency converge to elevate the standards of your manufacturing processes.

Crucible Melting Furnace For Aluminum Alloy Die Casting Machine

The crucible melting furnace, a pivotal component designed exclusively for aluminum alloy die casting machines. Positioned at the forefront of innovation, this furnace plays a pivotal role in redefining the crucial melting phase within die-casting processes. Let's delve into the intricate details of this advanced melting solution, meticulously crafted for precision, efficiency, and an elevation in die-casting capabilities.

Trimming Machine For Die-casting Machine Peripheral Equipment

The trimming machine, an essential element within die-casting machine peripheral equipment. Meticulously crafted, this precision tool is purposefully designed to elevate the efficiency of die-casting processes, placing a specific emphasis on the crucial trimming phase. Prepare to revolutionize your manufacturing capabilities with this cutting-edge trimming solution, meticulously crafted for precision, reliability, and optimal performance.

Auto Ladler Manipulator For Die-casting Machine Peripheral Equipment

The auto ladler manipulator, a crucial component within die-casting machine peripheral equipment. This state-of-the-art solution is purposefully designed to elevate the efficiency of die-casting processes, centering on the automation of ladling and manipulation tasks. Positioned as a transformative technology, this innovation promises to enhance manufacturing capabilities with its cutting-edge automation features.

Automatic Extracting Machine For Die Casting Machine Peripheral Equipment

Unveiling the automatic extracting machine, an integral element within die casting machine peripheral equipment. This state-of-the-art innovation is meticulously designed to revolutionize die casting processes by serving as a key player in the seamless extraction of casted products from molds. Its role is pivotal, aimed at enhancing overall efficiency and precision within peripheral equipment operations.

Auto Sprayer For Die Casting Machine Peripheral Equipment

The auto sprayer for die casting machine peripheral equipment – a cutting-edge solution designed to enhance the die casting process. This cutting-edge solution stands as a testament to advancements in manufacturing technology, particularly in peripheral equipment. The automated sprayer takes center stage, playing a pivotal role in elevating the die casting experience by ensuring unparalleled precision and efficiency in the application of release agents and lubricants to molds.

Automatic Smart Industrial Automatic Robot Telescopic Robot Arm For Injection Molding Machine

The automatic smart industrial robot telescopic arm for injection molding machine redefines automation in manufacturing. Tailored for injection molding, this intelligent robotic arm seamlessly integrates with machines, elevating efficiency and precision. Its telescopic design ensures flexibility and precise handling of diverse tasks, while smart features optimize real-time adaptability. The user-friendly interface allows effortless customization.

Air Cooled Machine Cooling For Injection Molding Industrial Water Chiller

The air cooled machine cooling for injection molding industrial water chiller stands as a revolutionary solution, meticulously crafted to redefine and elevate cooling processes in the realm of injection molding applications. This advanced chiller system represents a technological milestone, setting an innovative benchmark for precision temperature control and operational efficiency within the dynamic landscape of industrial settings.

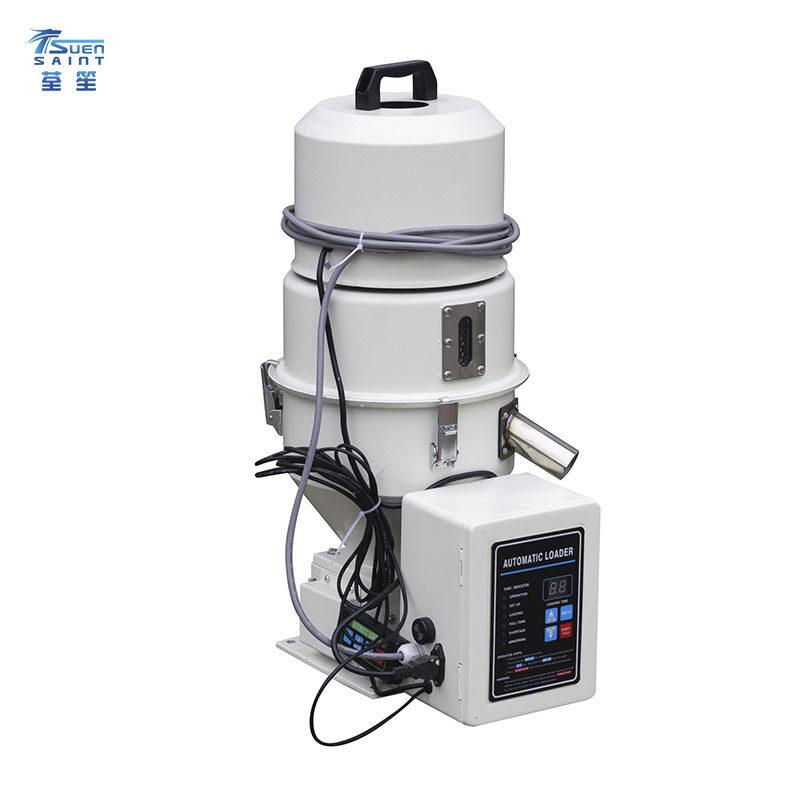

High Efficiency Standard Alone Auto Plastic Material Loader

The high efficiency standard alone auto plastic material loader is an innovative solution meticulously crafted to revolutionize material loading in industrial environments. This cutting-edge loader not only raises the bar for efficiency but also sets new standards for reliability. Its standalone design introduces a paradigm shift, ensuring a seamless integration that reshapes the landscape of plastic processing workflows.

Industrial Color Mixer Vertical Blender For Plastic Mixing

The industrial color mixer vertical blender, a game-changing solution for precise and efficient plastic mixing in industrial settings. This state-of-the-art blender is meticulously engineered to meet the demanding requirements of uniform color blending in plastic processing. With its innovative design and advanced features, it ensures optimal mixing performance, resulting in high-quality and consistent color distribution.

Plastic Raw Material Drying Oven Baking Machine Plastic Granule Hopper Dryer For Injection Molding

The plastic raw material drying oven baking machine, a cutting-edge solution for drying plastic granules in Injection Molding. This advanced equipment ensures optimal drying conditions, eliminating moisture and impurities. With precise temperature and airflow control, it enhances efficiency and reduces defects in the final products. User-friendly controls and durable construction make it a reliable choice.